Funded by the ERDF and the City of Pori, the Satakunta University of Applied Sciences' project Molten metal analysis methods to promote the circular economy (SUMEA) is investigating the technological level of copper smelters and their use and quantities of primary and recycled raw materials, as well as the barriers to increasing the use of recycled materials. The project will identify the state of the art in methods for the analysis of molten metal, investigate the feasibility of analysing molten metal by spectroscopic methods and identify applications where molten metal spectroscopy could be useful in industry.

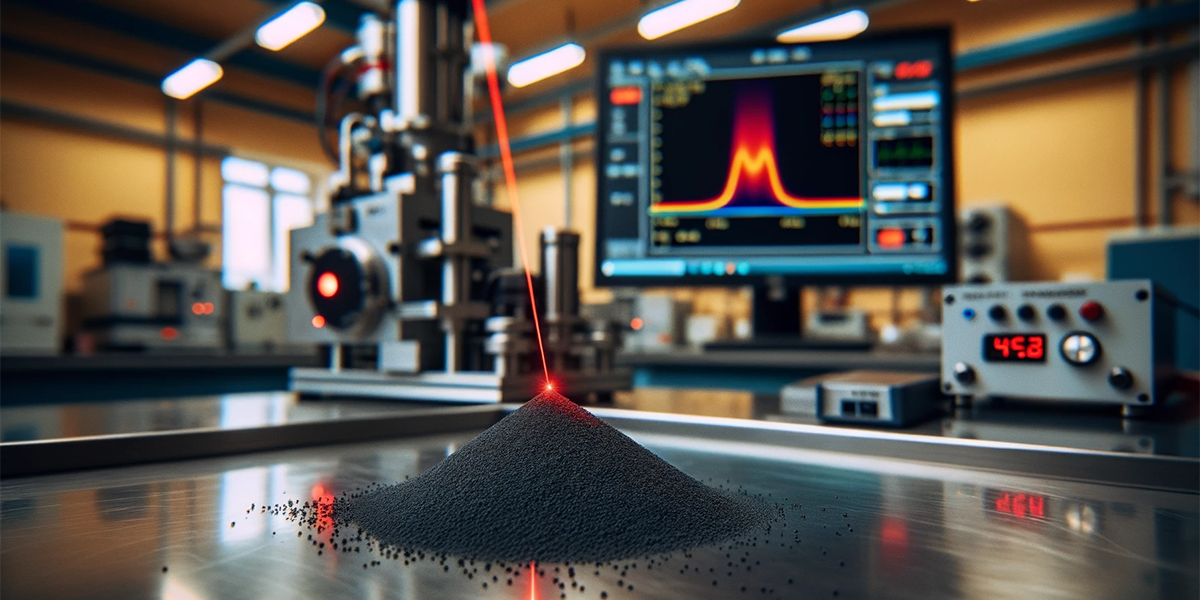

The AIST project will investigate whether AI-assisted laser spectroscopy can be used to identify batteries and their concentrations, and whether it can be used for recycling. Traditionally, laser spectroscopy has been pre-calibrated with the exact samples and elements of interest in the samples to be studied. The aim of using artificial intelligence is to bypass sample-specific calibration and thus extend the range of applications of laser spectroscopy.

The SUMEA project will investigate the level and methods of spectroscopy suitable for the analysis of molten metal and design an experiment under laboratory conditions to analyse molten metal using spectroscopy. At the same time, it will discuss with industry and identify applications and locations where molten metal spectroscopy could be piloted in the process industry at a later stage.

In the AIST project, artificial intelligence is trained with a large amount of spectral data of elements and battery compounds, both from the public spectral library and from own measurements. The aim is to teach the system to identify elements even in materials for which it has not been previously taught and for which the instrument has not been calibrated on these samples.

The analysis of molten metal by spectroscopic methods would offer great potential for monitoring material flows in the process industry and would allow better process efficiency if the process could be adjusted on the basis of continuous compositional monitoring. The composition of the available recycled raw material varies and on-line analysis would allow a rapid response to changes in the composition of the raw material.

If successful, the method developed in the AIST project could identify battery materials directly in the recycling process. This would allow materials to be more efficiently directed to the right downstream processes and the quality of the recycled fractions to be controlled.

Did you know?

- Spectroscopy is a method of analysing the radiation (e.g. light) received from an object of interest.

- Critical metals include cobalt (Co), tungsten (W), magnesium (Mg), lithium (Li), antimony (Sb), vanadium (V), copper (Cu) and nickel (Ni).

- The estimated amount of copper currently in use worldwide is 450 000 kilotonnes.