A student team from RoboAI Academy carried out a project for Tukimet Oy on how the palletizing phase of cardboard boxes could be automated with a collaborative robot, or “cobot” for short. Tukimet’s assembly area was laser-scanned, and a detailed 3D simulation model was built in the Visual Components software based on the point cloud. Using simulations, several cobot-based solutions were explored and their suitability for the company’s production was evaluated.

What was done in the project?

Tukimet Oy, based in Rauma, manufactures various Tyke® assistive devices, such as rollators. The finished products are packed in cardboard boxes. Some of these are large-sized boxes, weighing up to 14 kilograms. The boxes are manually stacked by employees onto FIN pallets in two layers.

The student team’s task was to investigate how a collaborative robot could reduce the physical strain of this phase and improve ergonomics. Tukimet had considered one type of a robot, but the choice had not yet been finalized – therefore the project also examined alternative models and solutions.

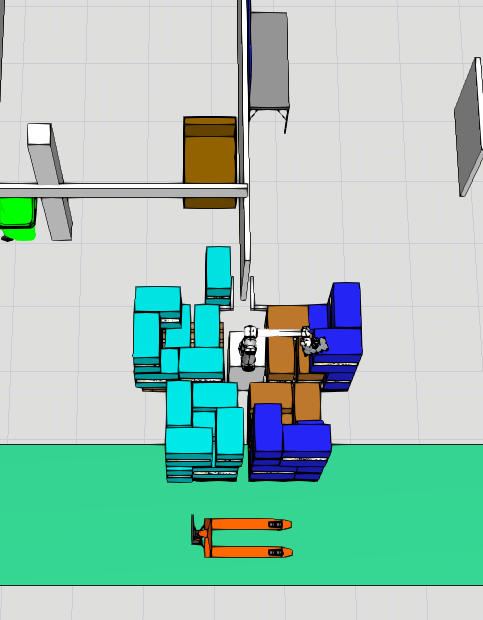

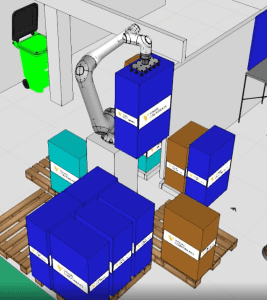

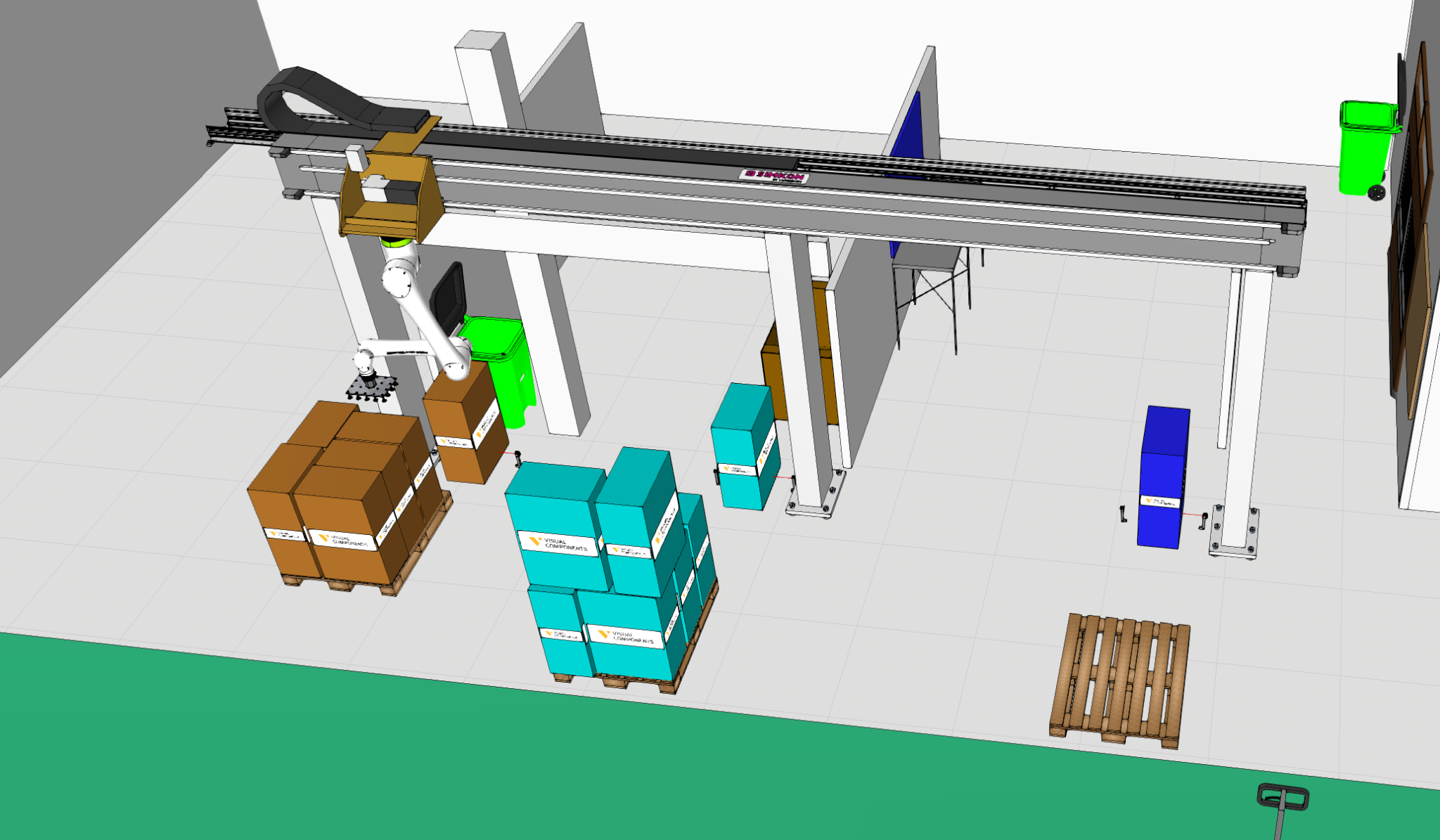

The assembly area was documented with photos and laser scanning. Based on the point cloud generated from the scan, 3D model of the workstations and pallet positions were created (Figures 1, 2). Different cobots, vacuum grippers and palletizing patterns were placed into the simulations to assess robot’s reach, the feasibility of serving multiple workstations with a single robot, cycle times relative to production pace, and the impact of each solution on safety and overall feasibility.

Results: a practical solution through simulation

In the first phase of the project, a layout was analyzed in which the example robot was positioned between two workstations. The operator would place a finished box at a pickup point, from which the robot would palletize it onto a FIN pallet. The simulation showed that this baseline solution works well for the most common box sizes, but with the largest boxes the reach and safety margins became uncertain in some positions.

In the further development phase, the same layout was tested with the larger robot model (Figure 3). The increased reach and higher payload clearly improved the situation, and the robot was able to reach all palletizing positions even with the largest boxes. This solution aligned best with Tukimet’s current way of working and reduced the amount of manual lifting.

The project also examined ceiling rail–mounted solution (Figure 4) and Doosan Robotics P3020 cobot (Figure 5), both of which would make it possible to serve more workstations and cover a larger working area. Both options proved technically viable but would require clearly greater investment and more extensive modifications to the premises. They are therefore better suited as long-term development directions than as the first solution to be implemented.

As a result of the project, Tukimet received simulation videos, layout images and a written summary of the strengths and limitations of the different cobot solutions, as well as their impact on ergonomics. At the same time, the student team gained valuable hands-on experience in combining laser scanning, robotics and simulation in a real industrial customer project.

Thanks to Tukimet for the great project topic!

More information about this and other RoboAI Academy projects:

Chief Researcher and Principal Lecturer

Mirka Leino

tel. 044 710 3182

mirka.leino@samk.fi

Researcher and Lecturer

Janika Tommiska

tel. 044 710 6332

janika.tommiska@samk.fi