Robotic welding is one of the most significant applications of industrial automation, and its use has grown rapidly. The basic idea is simple: instead of a traditional manual welder, welding is controlled by a programmed robotic arm that moves the welding torch precisely along a predetermined path. Several welding processes, such as MIG/MAG, TIG, and laser processes, are well suited for robotic welding and coating.

For small businesses, integrating robotic welding can be difficult, particularly due to investment costs, skill requirements, and production flexibility. Robotic systems are expensive to purchase and require programming skills and process reorganisation. In addition, the use of robots may seem difficult for small series and variable products

An external operator can help lower the threshold. It can provide a testing environment where the company can try out robotic welding without a large financial risk. The operator can also train personnel, develop programming models suitable for the company's needs, and help assess the profitability of the investment. This gives the company information, experience, and confidence in using robots in its own production.

The main objective of the European Union co-funded (JTF) project "Sustainable Growth for Engineering Workshops with Collaborative Robots" is to use RDI activities to renew and diversify the regional economy and business life in Satakunta and to promote the transition to a climate-neutral economy. The decline in peat production in Satakunta requires additional investment in RDI activities, such as the development of new operating models, innovations, and production processes, as well as making them available to companies for implementation.

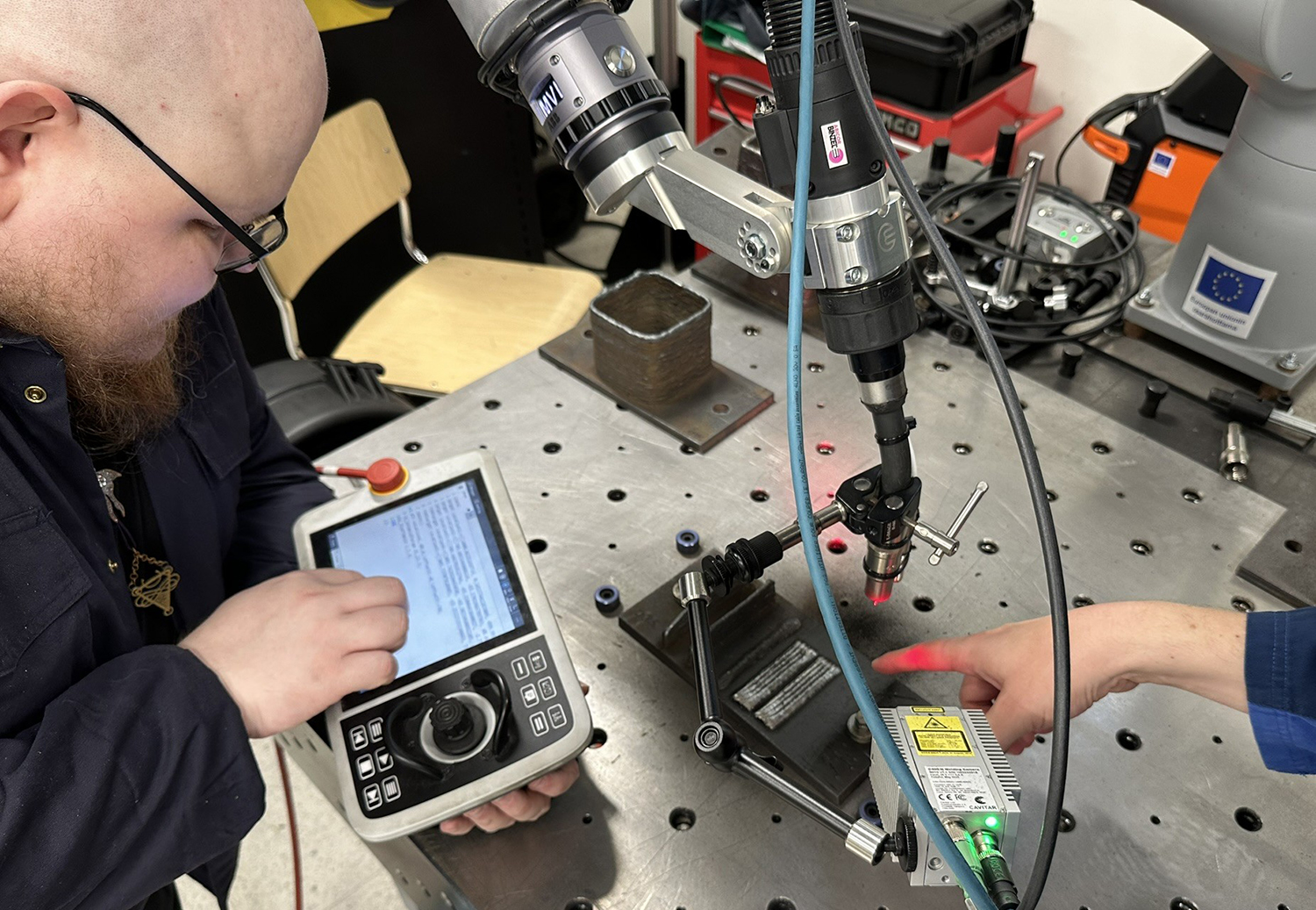

The project working group will carry out various welding tests using a MIG/MAG welding machine, and the results will be documented. Welding tests will be carried out on materials such as aluminum, structural steel, and stainless steel. Robotic welding is well suited for high-quality welding of materials that are difficult to weld by hand, as the robot moves the welding torch with steady speed and distance. The materials are subjected to butt and corner welds as well as coating welds with additives that prevent wear and corrosion. Some of the welds are used to produce samples for hardness measurements and microstructure studies.

The project also offers companies the opportunity to visit Satakunta University of Applied Sciences to learn about robotic welding and to conduct welding tests on materials and products of interest to the company.

The project's objectives support local SMEs by providing concrete means to improve production efficiency, quality, and competitiveness. The introduction of robotic welding and digital processes reduces material waste, energy consumption, and CO₂ emissions, which strengthens both cost-effectiveness and sustainable development.

Automation helps companies respond to labor shortages, as robots can handle repetitive and heavy work tasks, allowing staff to focus on more demanding tasks. At the same time, employees' skills develop through robotics and programming, which ensures business continuity and lays the foundation for new innovations.

The tests, calculation models, and practical examples produced by the project lower the investment threshold for companies and demonstrate the concrete benefits of robotic welding. This can open up new markets for SMEs, enable the manufacture of new products, and strengthen the vitality of the entire Satakunta business community.

Did you know?

Did you know?

- In addition to quality, welding robots improve occupational safety and enable welding in places where humans cannot weld, such as various types of tanks.

- In addition to welding, robots can also be used to assist in surface treatment. By changing tools, the robot can be equipped with a grinder or paint sprayer when welding is not required.

- The first welding robots were introduced in the 1960s in car factories, where they were used for spot welding.